The SBDC gave us structure and strategy. When you’re a small manufacturer, you wear every hat, marketing, logistics, engineering, finance, so having someone outside who can see the whole picture matters.

David Reed

THE MEMORY OF METAL

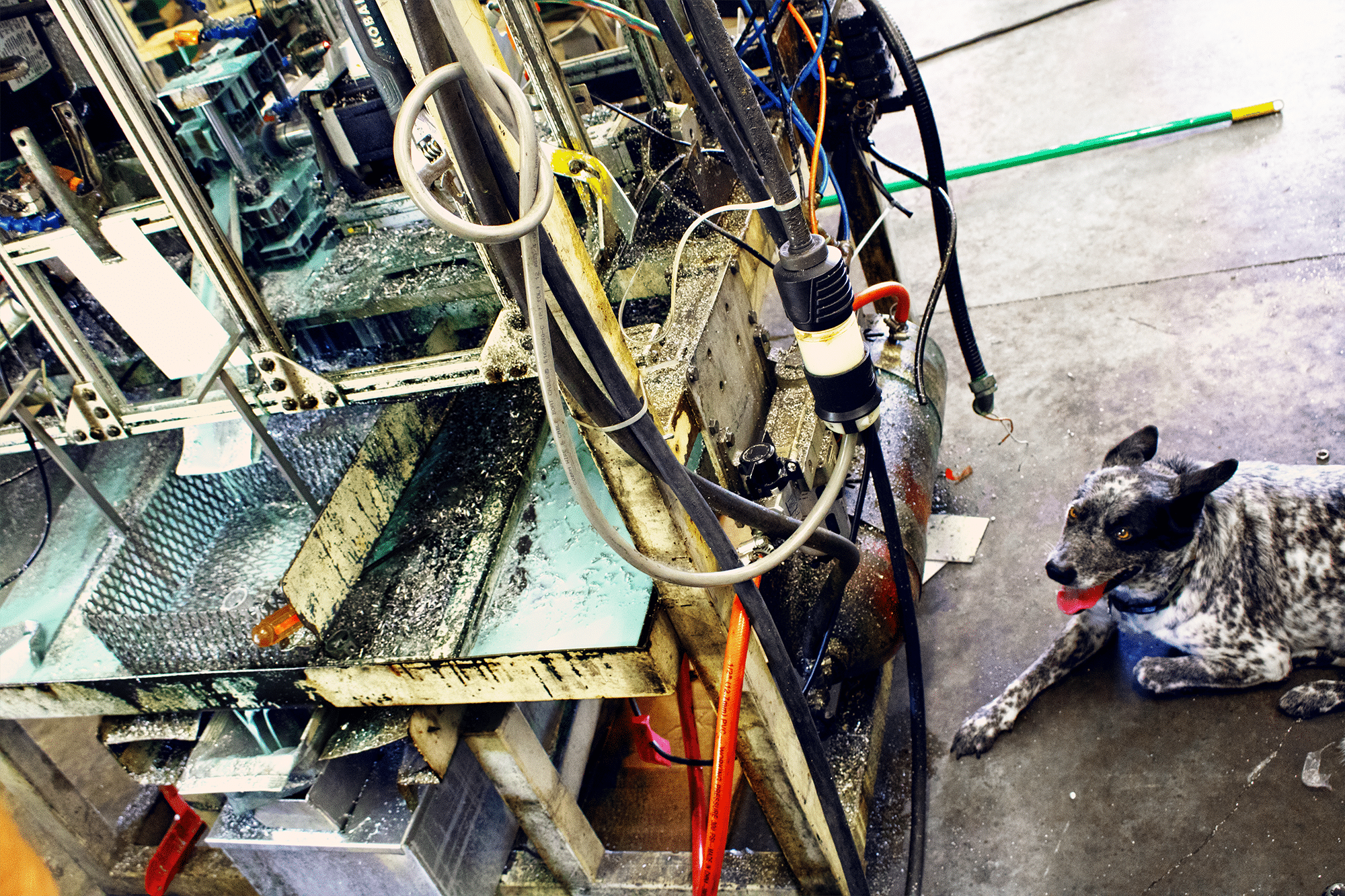

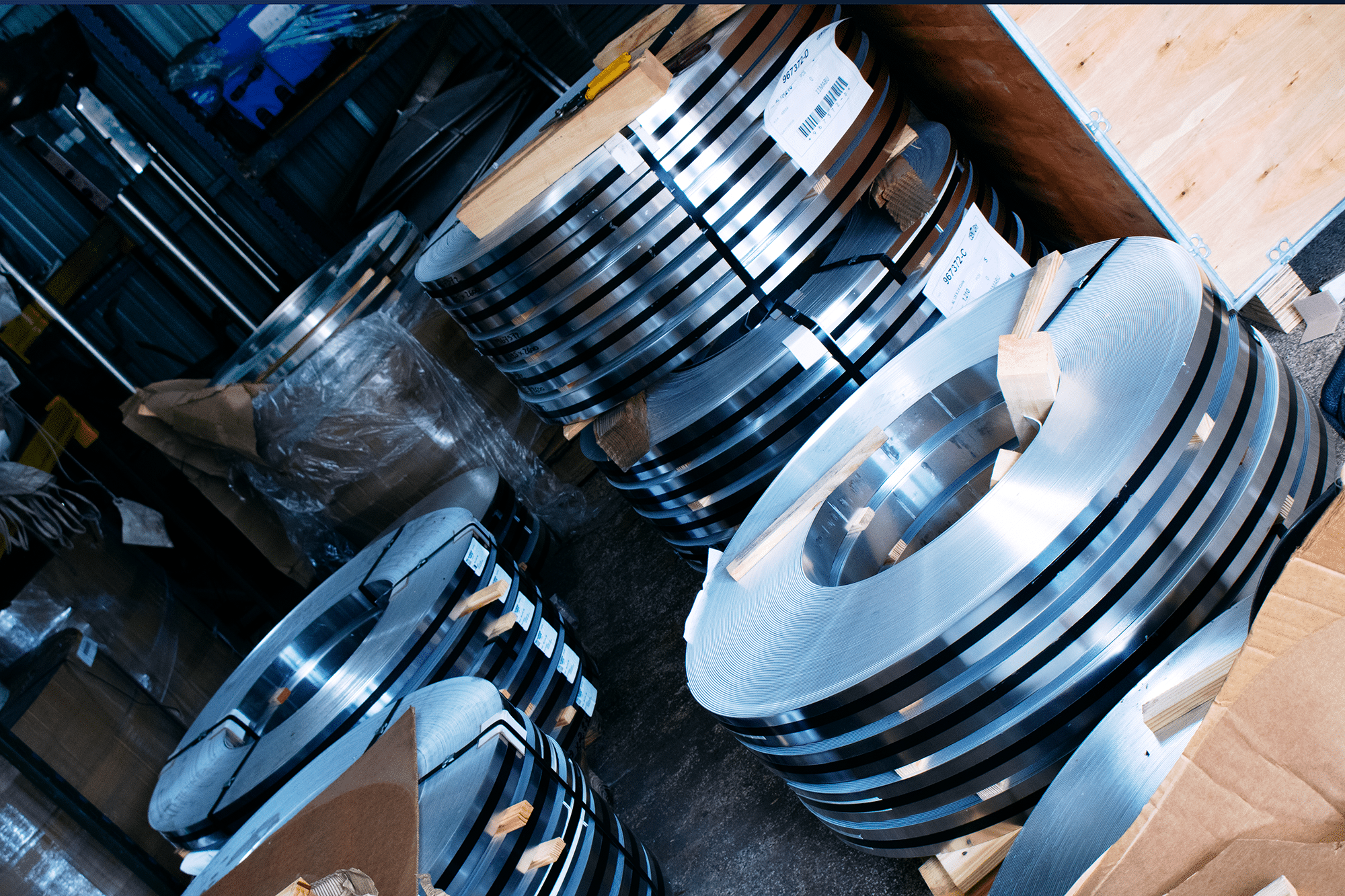

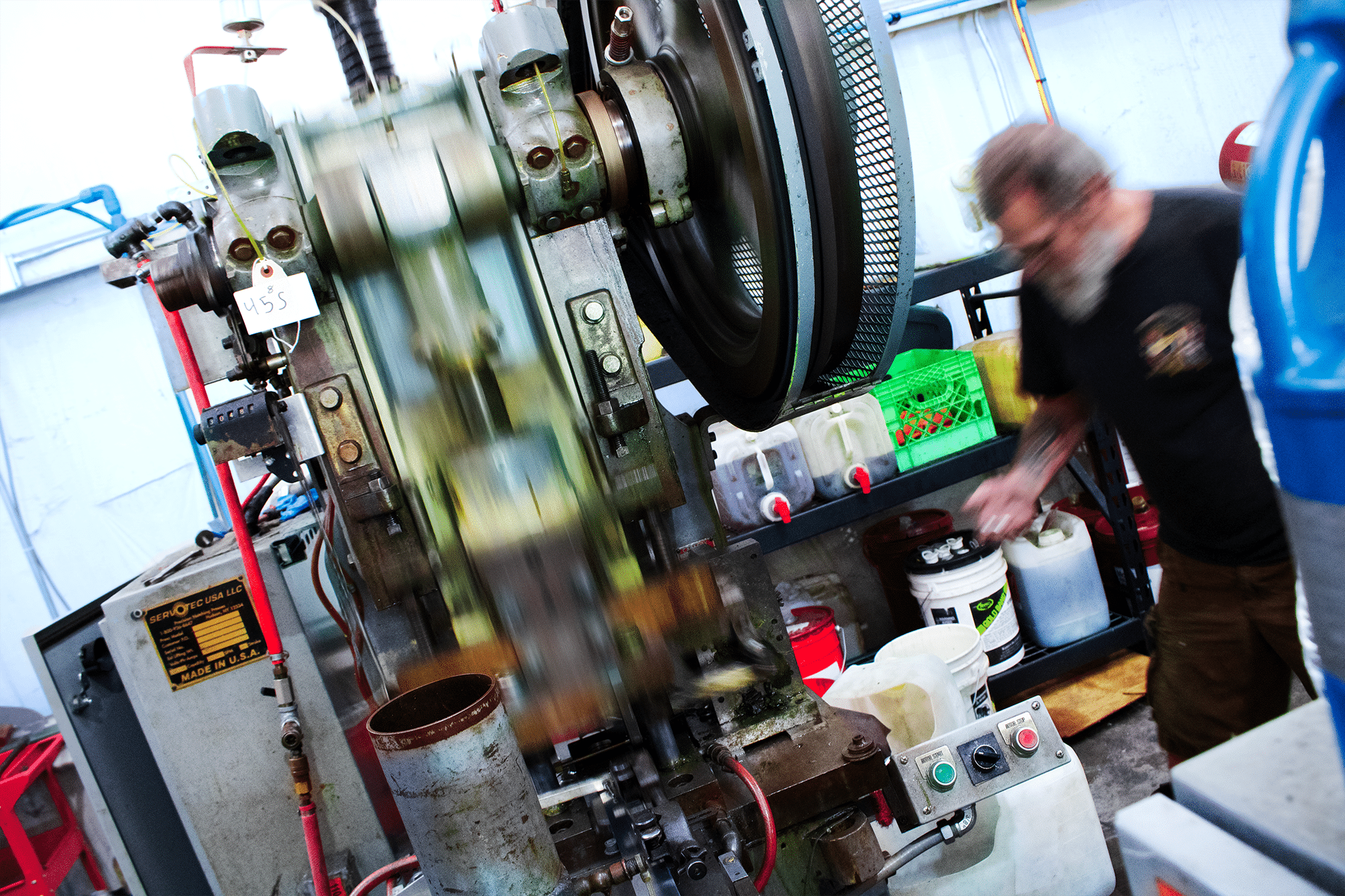

In the quiet industrial stretch of Moore Haven, the hum of machinery rises above the heat. Inside the warehouse, soft morning light drifts through the open bay doors, catching on rows of polished aluminum and bins of metal buttons that glint like coins from another era. Here, Lucy and David Reed are running a business that bridges this century of American manufacturing with the last.

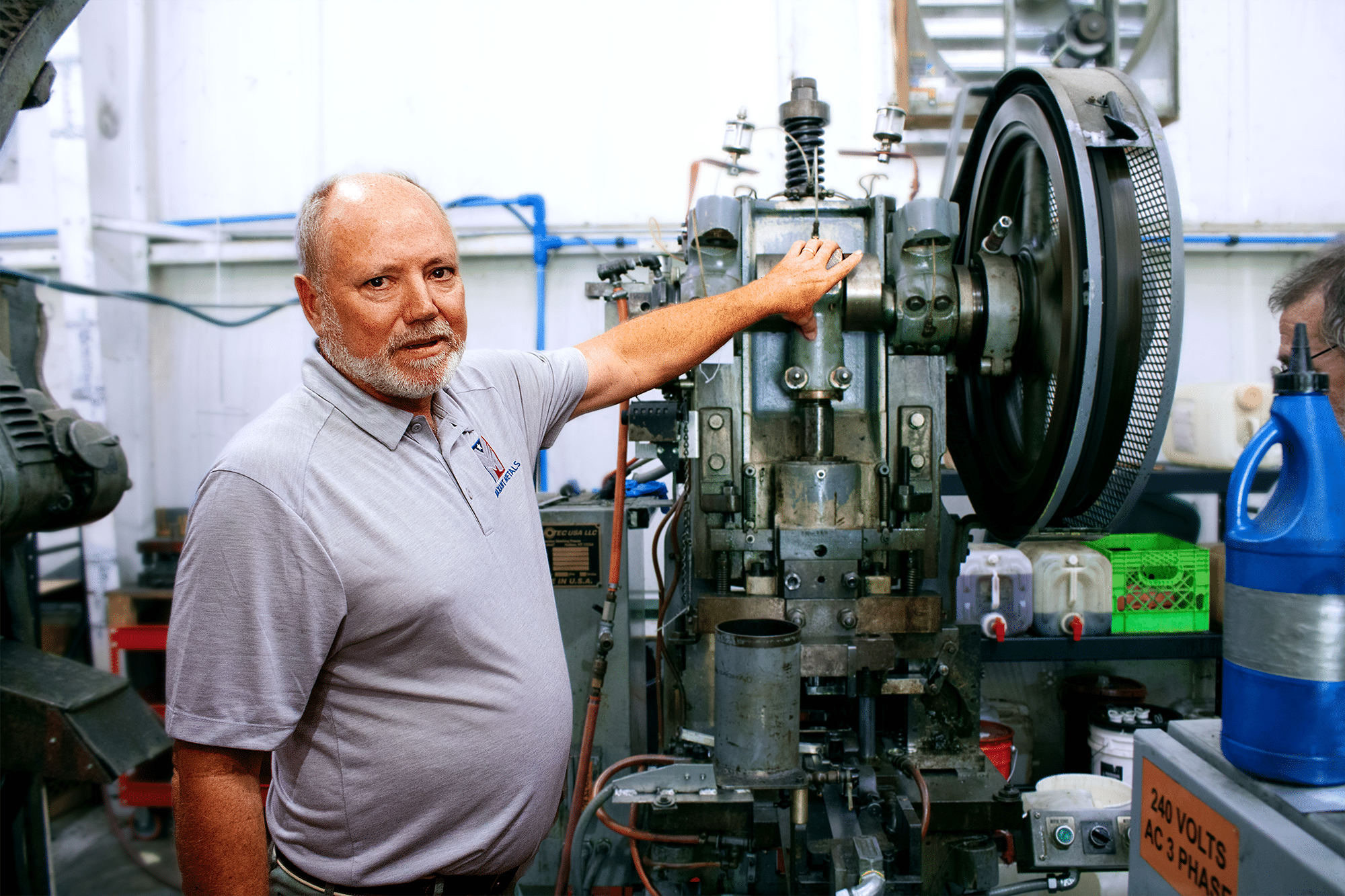

“We came here as a button factory,” David says with a wry grin, looking toward the section of the building still filled with vintage machines from the 1960s. “We were buying and selling these buttons online, and one day the factory just stopped answering their phone. That was the beginning.”

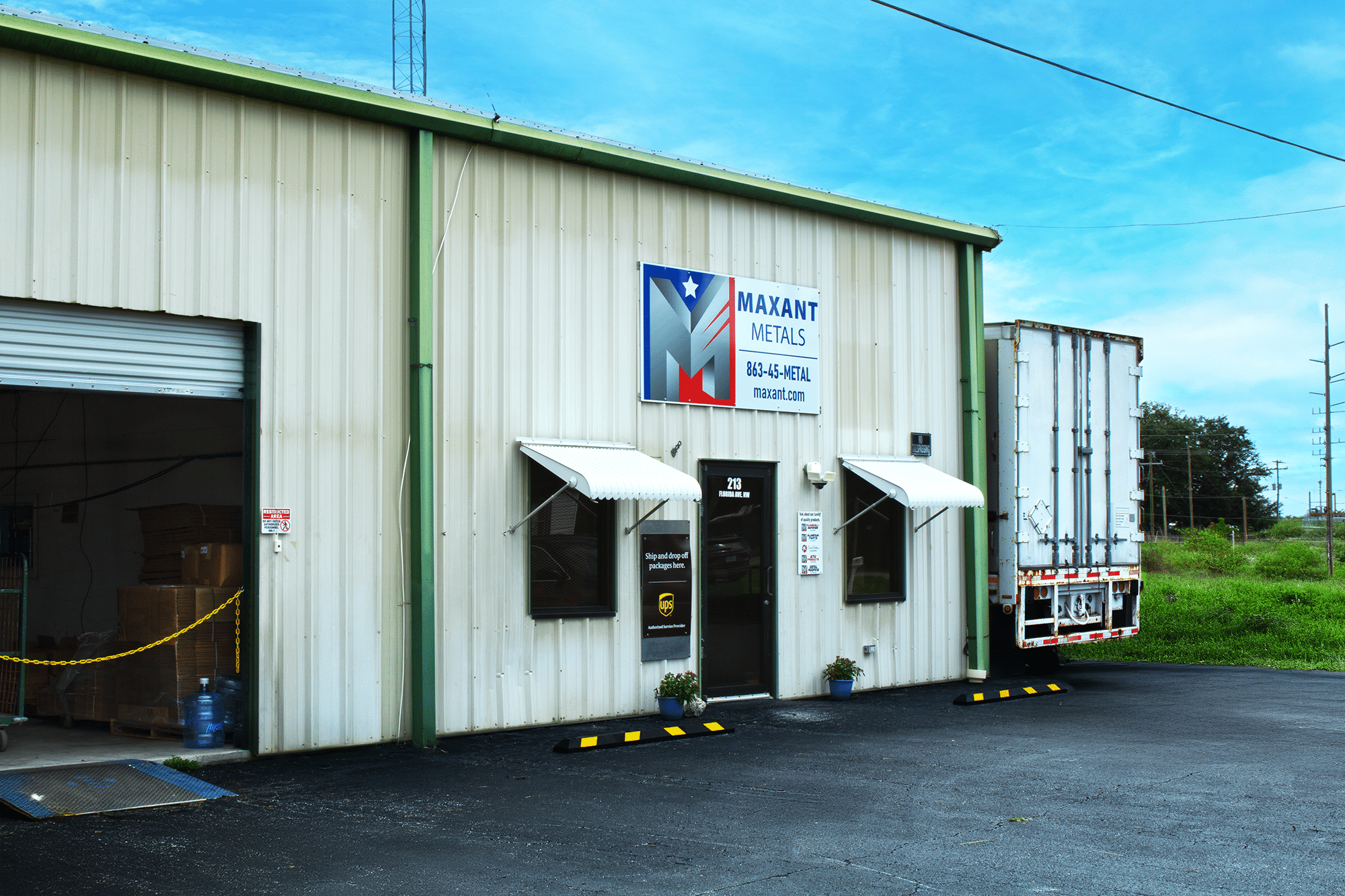

What began as a small family venture, a niche trade in fabric-covered buttons once used by designers and seamstresses worldwide, has evolved into Maxant Metals, a multi-division manufacturing company producing everything from clamshell awnings and roofing panels to aluminum components for screen enclosures and ATVs. The path from Fort Lauderdale to Moore Haven was not planned. It was, as Lucy puts it, “a leap of faith that just happened to work.”

A Factory Reclaimed

The Maxant story began in Atlanta, where the original manufacturer of cover buttons, a once-booming Chicago company, had gone bankrupt for the second time. “My parents were selling their products online at the time,” David recalls. “They got a call from someone who couldn’t reach the factory. Within days, we realized we might lose the supply chain entirely.”

Instead of watching the business disappear, the family made a decision that would define their future. They bought the assets directly from the bank, saving the old machinery and the brand itself. “We had no idea what we were doing,” David admits. “You wouldn’t write it down as a plan. Go buy all these old machines, make new dies, start making products again. But that’s what we did.”

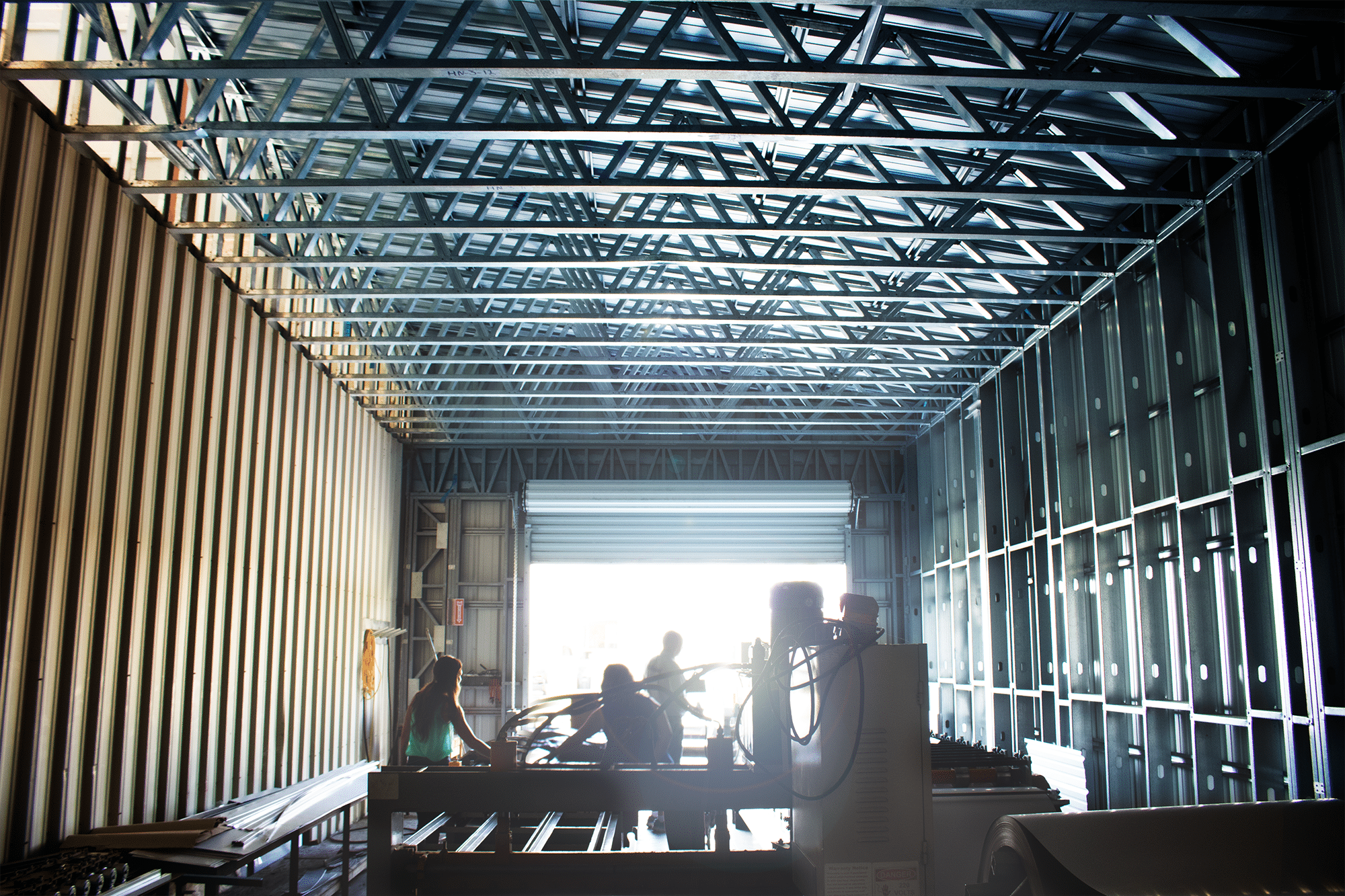

When the opportunity came to relocate the operation, they looked inland. Fort Lauderdale was expensive and congested. Moore Haven, by contrast, offered affordability, space, and the kind of quiet that invites focus. “We bought the building from the bank,” David says. “The grass was as high as your shoulders, the place was empty, but it had power, and that was enough.”

By the fall of 2016, the Reeds had moved everything south from Georgia, an entire factory transported in convoys of 26-foot Ryder trucks. “The last truck left Atlanta on election night,” David recalls. “Two trucks, back to back, so no one could steal anything.”

Building Five Divisions

Over the next decade, Maxant Metals grew into five divisions: cover buttons, aluminum products, clamshell awnings, roofing panels, and a line of ATV and utility vehicle accessories. The diversity was both strategic and necessary. “You’re either growing or dying,” David says. “Every penny I have extra, I reinvest in the business.”

COVID-19, which devastated so many companies, gave Maxant a temporary surge. “People were home, fixing things, crafting,” Lucy explains. “Everything we sell, buttons, parts, awnings, fit into that moment.” It also gave them time to restructure. The Reeds acquired new machinery, expanded storage, and modernized their operations.

Their approach has always combined practicality with adaptability. “I’ve done this enough times to know when not to do something,” David says, referring to past ventures that taught him how to manage risk. That mix of caution and confidence carried into their most ambitious move yet, developing a roofing division that meets Florida’s stringent high-wind certification standards.

“It’s been our biggest challenge,” he admits. “You can’t just make a product. You have to prove it meets code, get engineers to test it, and pay for the certification. It’s tough for a small business, but we’re getting there.”

Guidance from the SBDC

That steady progression, from survival to expansion, has been guided in part by the Florida Small Business Development Center (SBDC) at Florida Gulf Coast University, and consultant Andrea Walker, who began working with the Reeds during their transition to Moore Haven.

“She’s been priceless,” Lucy says. “Andrea helped us consolidate what used to be four separate, failing websites into one strong, unified platform. She gave us direction, not just marketing ideas, but a sense of how to manage our time and how to think about growth in realistic ways.”

David agrees. “It wasn’t about fixing one problem. It was about learning how to manage the many things we had built. The SBDC gave us structure and strategy. When you’re a small manufacturer, you wear every hat, marketing, logistics, engineering, finance, so having someone outside who can see the whole picture matters.”

With Andrea’s help, Maxant Metals streamlined its brand identity, expanded its online visibility, and improved its outreach in Glades County and beyond. “We’ve built a real relationship,” Lucy adds. “If I don’t have an answer, I know who to call.”

Rooted in Moore Haven

Nearly a decade after their relocation, the Reeds have become part of the town’s fabric. Their property doubles as a manufacturing hub and a community touchpoint, a UPS drop-off site, a casual showroom, and a gathering place for customers curious about the company’s eclectic product line. “People walk in and say, ‘I didn’t know you were here,’” Lucy laughs. “Now they come in for screws, roofing pieces, or just to see what we’re making.”

Maxant Metals continues to grow, sometimes in quiet, unseen ways. The company recently purchased a new set of imported machines to expand their roofing division and has reinvested through Opportunity Zone funding, a strategy the SBDC helped them navigate. “We’re probably the smallest business in America to take advantage of that,” David says with a smile.

Through all of it, their philosophy remains simple: reinvest, improve, and stay steady. “We’re just hitting our stride,” Lucy says. “It takes fifteen years to feel like an expert in your field. We’re ten years in, give us five more.”

A Future Forged in Metal

In the bright light of a Florida afternoon, the machinery at Maxant Metals whirs to life again, a pulse of progress in a small rural town. The building still carries the echoes of the past: the old button presses from Chicago, the smell of metal and oil, the sound of possibility.

For Lucy and David Reed, growth has never been about chasing the next big thing. It is about preserving what works, refining what does not, and finding new ways to create lasting value for their customers, their employees, and their community.

“The SBDC helped us see what we already had,” Lucy reflects. “Sometimes you just need someone to remind you that you’re building something that matters.”