To sit down with someone of their caliber and breadth of experience—that’s invaluable. You just don’t get that everywhere.

Doug Cramer

The Quiet Custodians of Flight: RexAir Flight and Maintenance’s Role in Aviation Safety

RexAir Flight and Maintenance operates without fanfare, grounded in the principles of precision and trust that define aviation safety. In the aftermath of COVID-19, Doug Cramer moved his family and relocated from Columbus, Ohio, to purchase RexAir from an English businessman. The company began as an extension of Cramer’s hands-on experience as a pilot and flight instructor. “I’ve been flying since I was in my 20s. It started as a passion, not a career,” he reflects. Recognizing a gap in consistent, quality maintenance for private and light commercial aircraft, Cramer assembled a small team to address the practical needs of local aviators. There were no grand ambitions, only a determination to get it right from the start.

In its earliest days, RexAir Flight and Maintenance was a lean operation, focused on small-scale upkeep and repairs. “The previous owner had driven the maintenance side into the ground. We had to talk to stakeholders and let them know it was under new ownership, with new methods,” Cramer recalls. The company worked to rebuild trust in the aviation community by maintaining meticulous standards and demonstrating reliability. This commitment earned RexAir solid endorsements through word-of-mouth, steadily increasing its workload. Growth came not through aggressive expansion but as a natural outcome of doing the job well, every time.

The Work Behind Every Takeoff

Cramer’s approach to growth has been pragmatic and deliberate. “We’ve tripled the maintenance department’s size and revenue output in just three years,” he says, underscoring the scale of RexAir’s evolution. The addition of a concierge maintenance service further distinguished the company. This white-glove offering provides aircraft owners with prepaid annual inspections, expedited scheduling, and retrieval services for planes from hangars. “It’s a white-glove service,” Cramer explains, “and it’s tailored to meet the exclusive needs of our clients.”

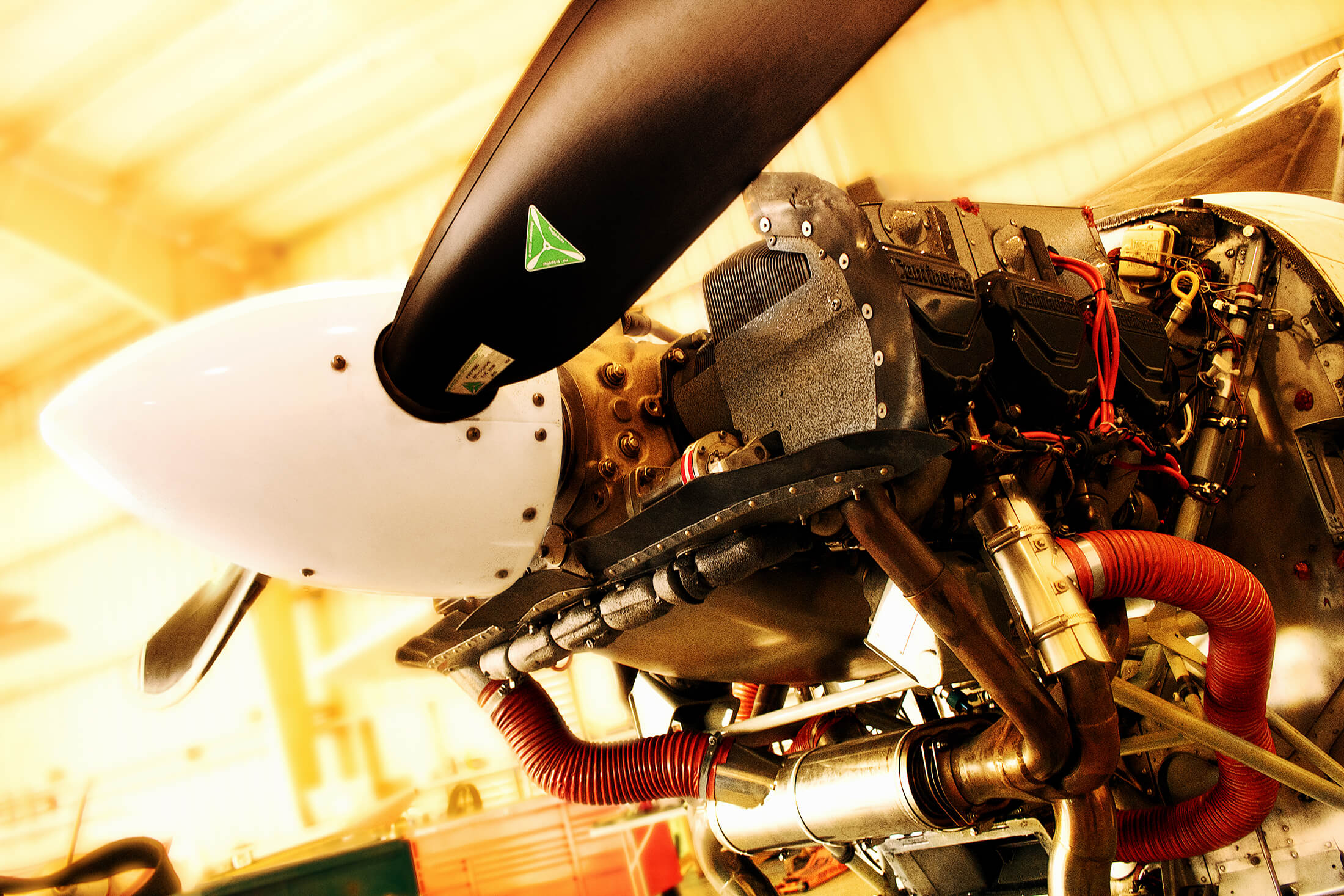

With a team of six to seven full-time mechanics operating under Cramer’s leadership, the maintenance division handles a range of essential services. These include routine 50-hour inspections, in-depth 100-hour inspections, oil changes, engine overhauls, avionics diagnostics, and structural repairs. The team often performs detailed internal checks, removing access panels to examine critical systems and ensure airworthiness. The facilities are constantly in use, with planes rotated in and out for servicing, creating a dynamic workflow.

Navigating a Niche Industry

The flight school at RexAir has also played a vital role in its growth. Based in the expanded hangar funded through an SBA 7(a) loan facilitated by the Small Business Development Center (SBDC), the school provides comprehensive training for aspiring pilots. Certified Flight Instructors (CFIs) train students in foundational skills, but retention of CFIs remains an industry-wide challenge. “After about 1,000 flight hours, CFIs leave to join airlines. That’s the nature of the industry,” Cramer explains. Despite this, RexAir’s flight school continues to be a cornerstone of its operations, contributing to the company’s reputation as a well-rounded aviation service provider. The SBDC’s influence on RexAir has been significant. “It ended up being $300,000 to renegotiate the land lease for the hangar.

The SBDC guided us through the process, helping us secure a 7(a) loan to fund the build-out,” Cramer recounts. Their advisors also assisted in streamlining operational workflows and provided actionable recommendations to address space constraints. “To sit down with someone of their caliber and breadth of experience—that’s invaluable. You just don’t get that everywhere,” he adds. The new hangar not only expanded RexAir’s maintenance capacity but also housed the flight school, creating a synergistic environment for maintenance and education.

Cramer’s experience operating in the unique Naples business climate has also shaped RexAir’s trajectory. “In Naples, nobody cares about bank processes because there’s always someone ready to buy with cash,” he notes, highlighting the financial hurdles RexAir overcame to secure funding in a competitive, cash-heavy market.

Today, RexAir Flight and Maintenance is a trusted name among pilots and aircraft owners across Southwest Florida. Its facilities hum with activity, from routine inspections to intricate repairs, each task handled with the same care that defined its beginnings. The addition of the flight school and concierge service has further cemented RexAir’s role as a cornerstone of the local aviation community, providing both technical services and educational opportunities. “It’s not about chasing volume. It’s about doing the job right every time,” Cramer emphasizes, reflecting the ethos that continues to guide the company.